OUR TECHNOLOGY

Throughout the years, we at Fukuvi, have continued to add & perfect new extrusion methods to our catalogue of capabilities. At Fukuvi Vietnam, we have the most requested extrusion methods available for OEM use, while at the same time we manufacture our own branded products using the same technologies. We are constantly manufacturing products using all of the different extrusion methods, which means that our employees are continuously gaining experience & never are out of practice.

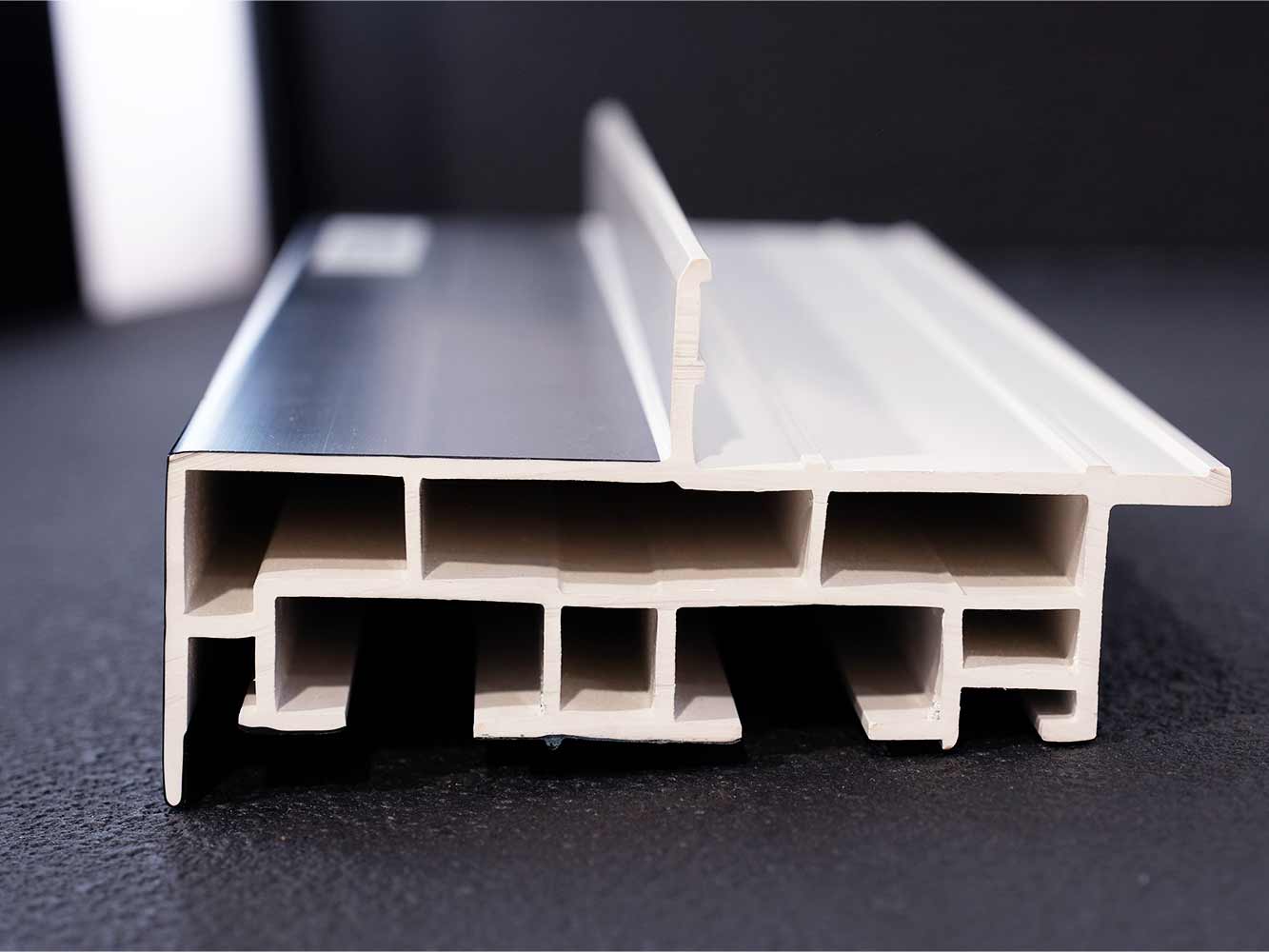

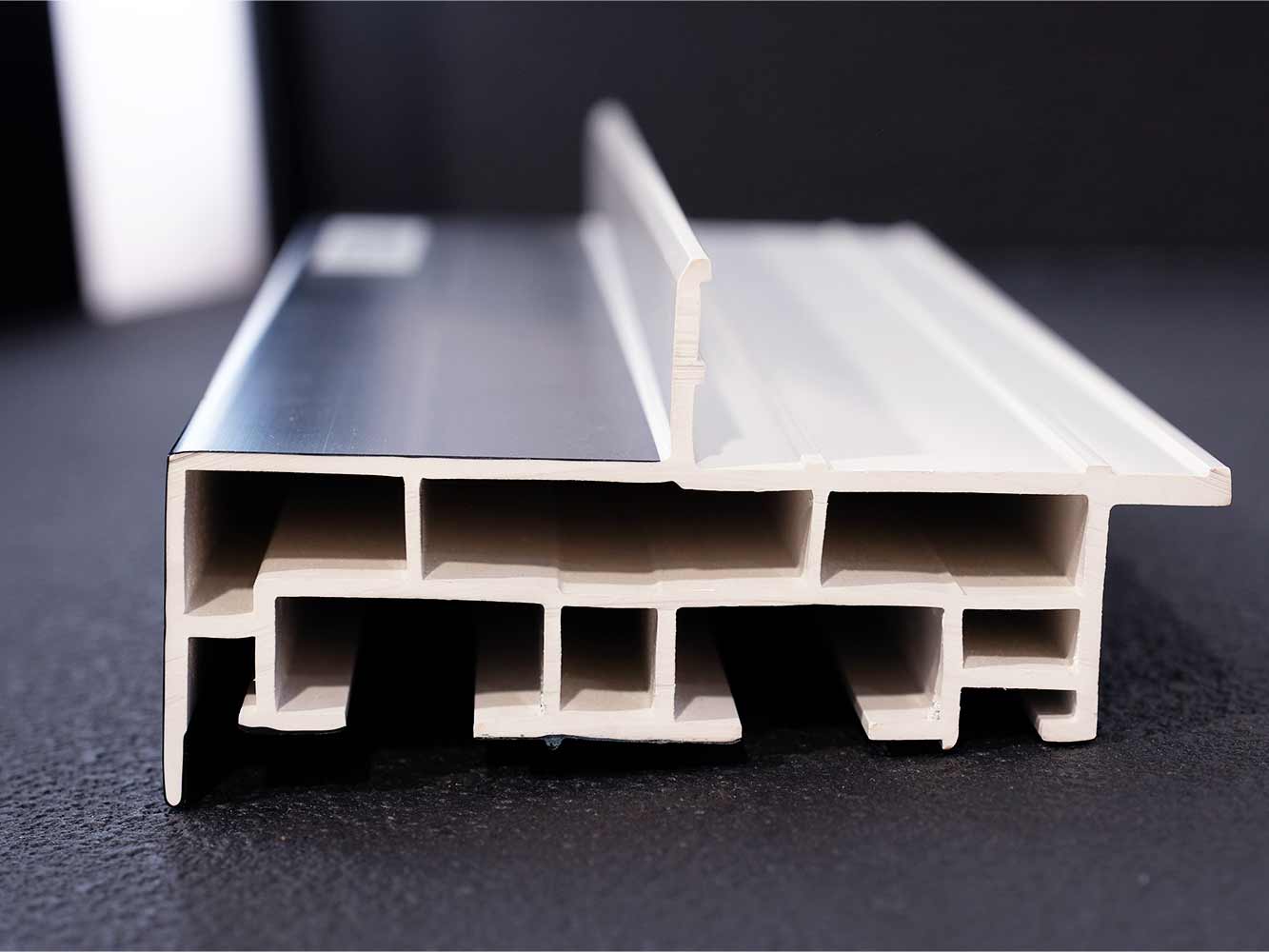

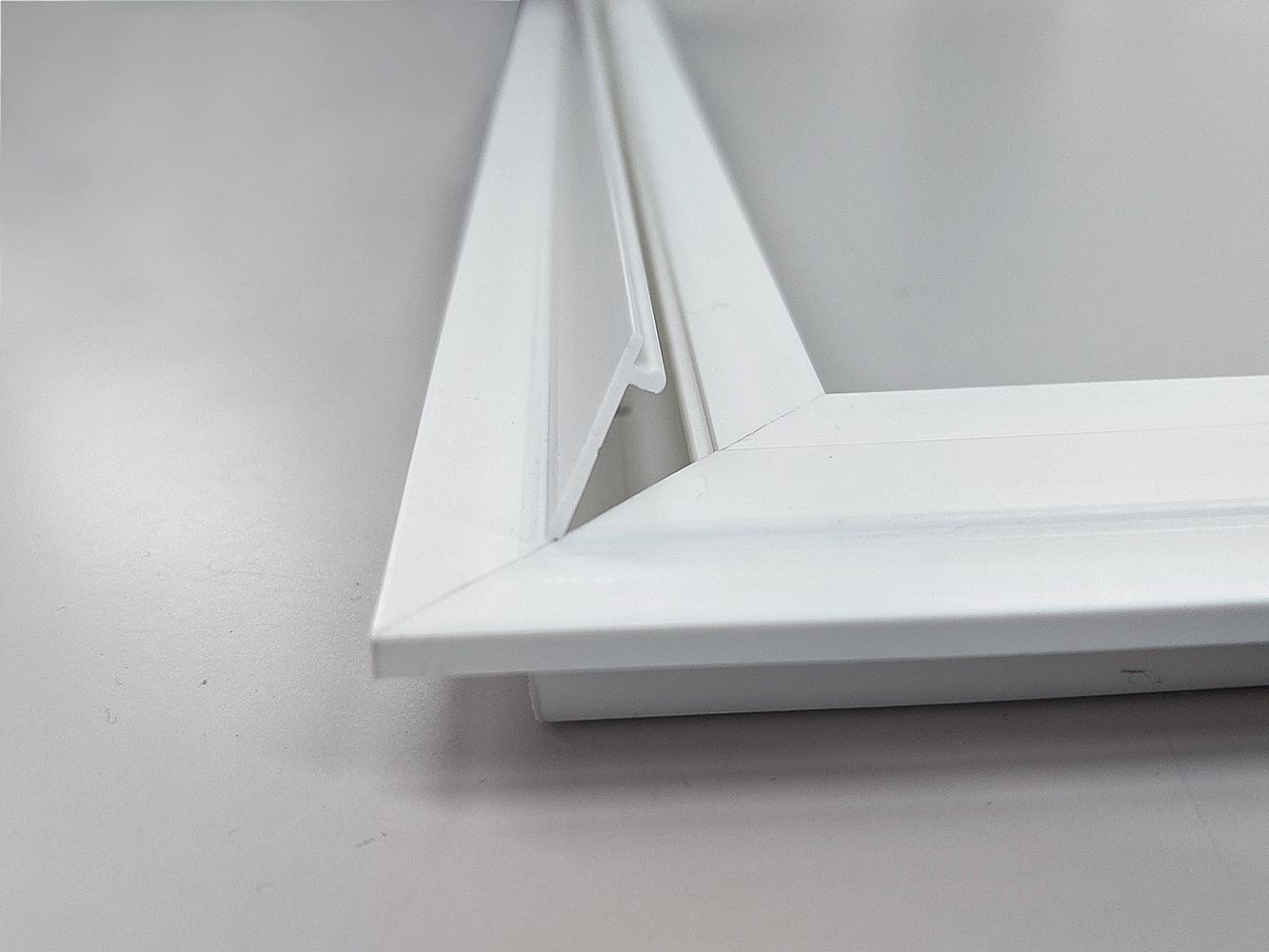

CO-EXTRUSION

Co-extrusion is Fukuvi’s core capability. We can extrude rigid and flexible materials together for a dual durometer extrusion with added value and function. We can also co-extrude different types of materials for improved cosmetic surfaces or weather resistant performance. Extrusion molding is capable of producing very complex cross-sections and using multiple materials in a single mold.

CO-EXTRUSION

Co-extrusion is Fukuvi’s core capability. We can extrude rigid and flexible materials together for a dual durometer extrusion with added value and function. We can also co-extrude different types of materials for improved cosmetic surfaces or weather resistant performance. Extrusion molding is capable of producing very complex cross-sections and using multiple materials in a single mold.

MATERIAL COMBINATIONS

Fukuvi can expertly co-extrude a product which combines two different materials. Combining multiple materials allows you to create enhanced functions and add high value to the parts we extrude.

Benefits of combining materials:

- Combine a light-weight interior with a hard, durable surface

- Combine different colors for enhanced style

- Combine hard and soft materials in order to create a stable product with a hinge or cushion

MATERIAL COMBINATIONS

Fukuvi can expertly co-extrude a product which combines two different materials. Combining multiple materials allows you to create enhanced functions and add high value to the parts we extrude.

Benefits of combining materials:

- Combine a light-weight interior with a hard, durable surface

- Combine different colors for enhanced style

- Combine hard and soft materials in order to create a stable product with a hinge or cushion

DECORATIVE PRODUCTS

Using co-extrusion we can create products with added design elements.

Examples include:

- Metallic

- Brushed Aluminum

- Wood Grain

- Bamboo

- Embossing

- ETC....

DECORATIVE PRODUCTS

Using co-extrusion we can create products with added design elements.

Examples include:

- Metallic

- Brushed Aluminum

- Wood Grain

- Bamboo

- Embossing

- ETC....

FUNCTIONALITY

Fukvui can add various functions to products using our superior co-extruding techniques.

Examples include:

- Increased weather resistance (add PMMA to the surface of base materials)

- Phosphorescence/Luminescence

- Antibacterial/Antiviral surface

- Hinges

- Etc...

FUNCTIONALITY

Fukvui can add various functions to products using our superior co-extruding techniques.

Examples include:

- Increased weather resistance (add PMMA to the surface of base materials)

- Phosphorescence/Luminescence

- Antibacterial/Antiviral surface

- Hinges

- Etc...

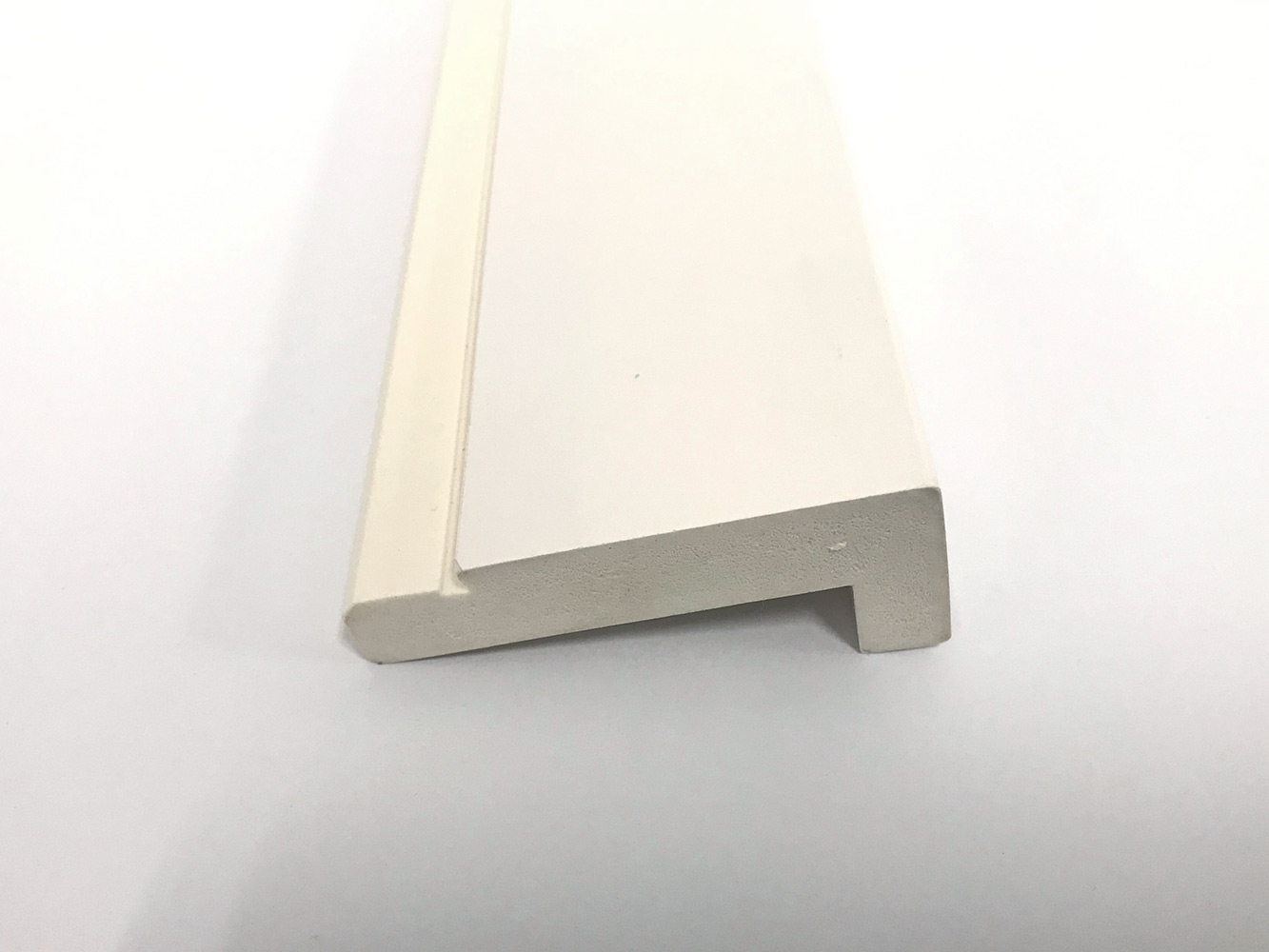

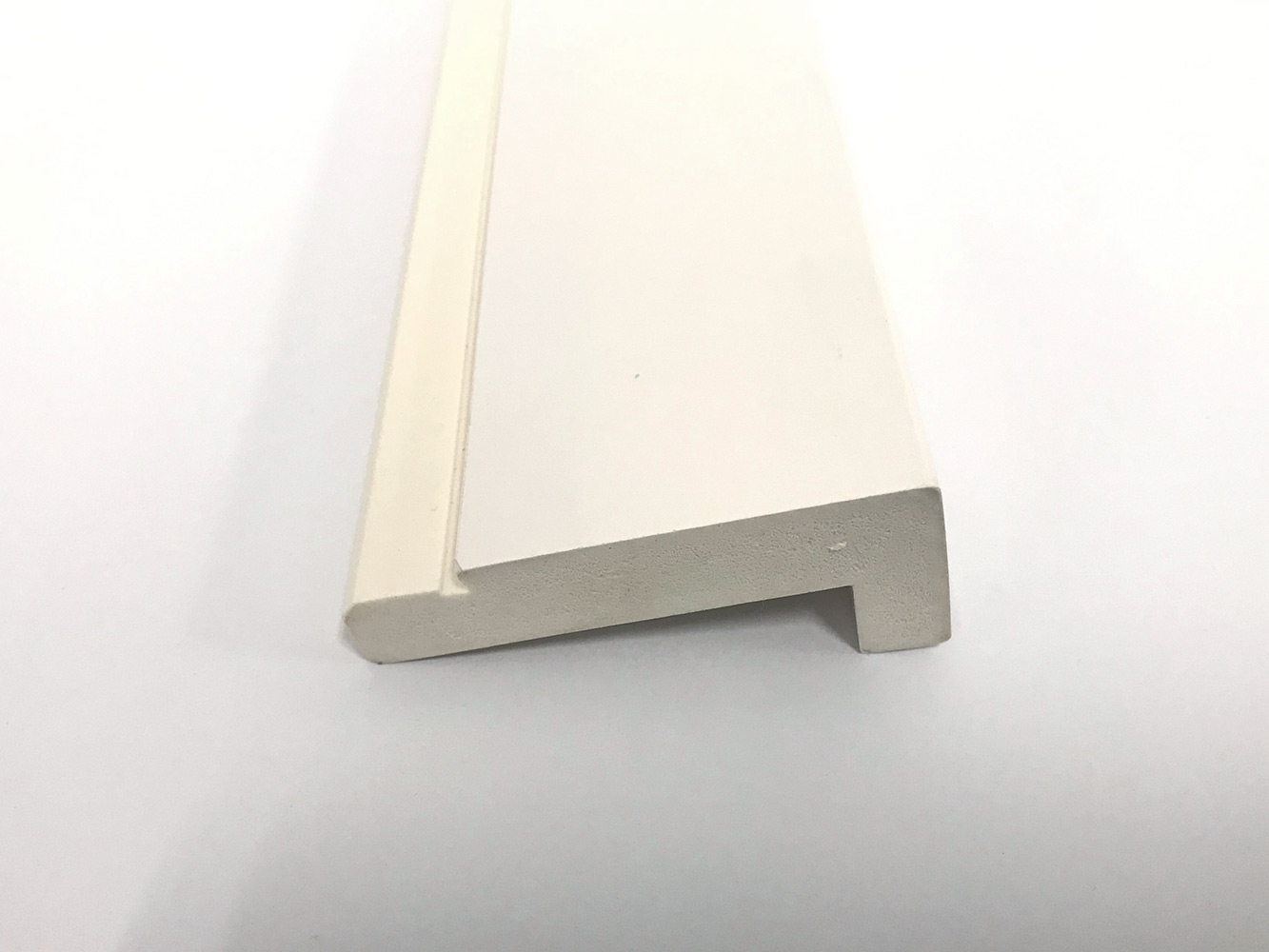

FOAM EXTRUSION

Using foam extrusion molding we can create products which are lighter than wood or metal, yet still durable. It is also easier to drive nails and screws in thick foam products, improving workability. Foam extrusion products also have improved heat insulation performance compared to other materials.

FOAM EXTRUSION

Using foam extrusion molding we can create products which are lighter than wood or metal, yet still durable. It is also easier to drive nails and screws in thick foam products, improving workability. Foam extrusion products also have improved heat insulation performance compared to other materials.

FOAM EXTRUSION

Using foam extrusion molding we can create products which are lighter than wood or metal, yet still durable. It is also easier to drive nails and screws in thick foam products, improving workability. Foam extrusion products also have improved heat insulation performance compared to other materials.

LAMINATION / FILM / ADHESIVES

By attaching an aluminum film we can create products which have metallic designs while keeping the high functionality of plastic. These are great substitutes for metal products. We can also add double-sided tape or masking tape to products.

LAMINATION / FILM / ADHESIVES

By attaching an aluminum film we can create products which have metallic designs while keeping the high functionality of plastic. These are great substitutes for metal products. We can also add double-sided tape or masking tape to products.

STRETCHING (SWAGGING)

By stretching the plastic while extruding it (also known as swaging) we can add strength to our extruded products. Depending on the resin mixture and stretching method used spring and wire characteristics can be added.

STRETCHING (SWAGING)

By stretching the plastic while extruding it (also known as swaging) we can add strength to our extruded products. Depending on the resin mixture and stretching method used spring and wire characteristics can be added.

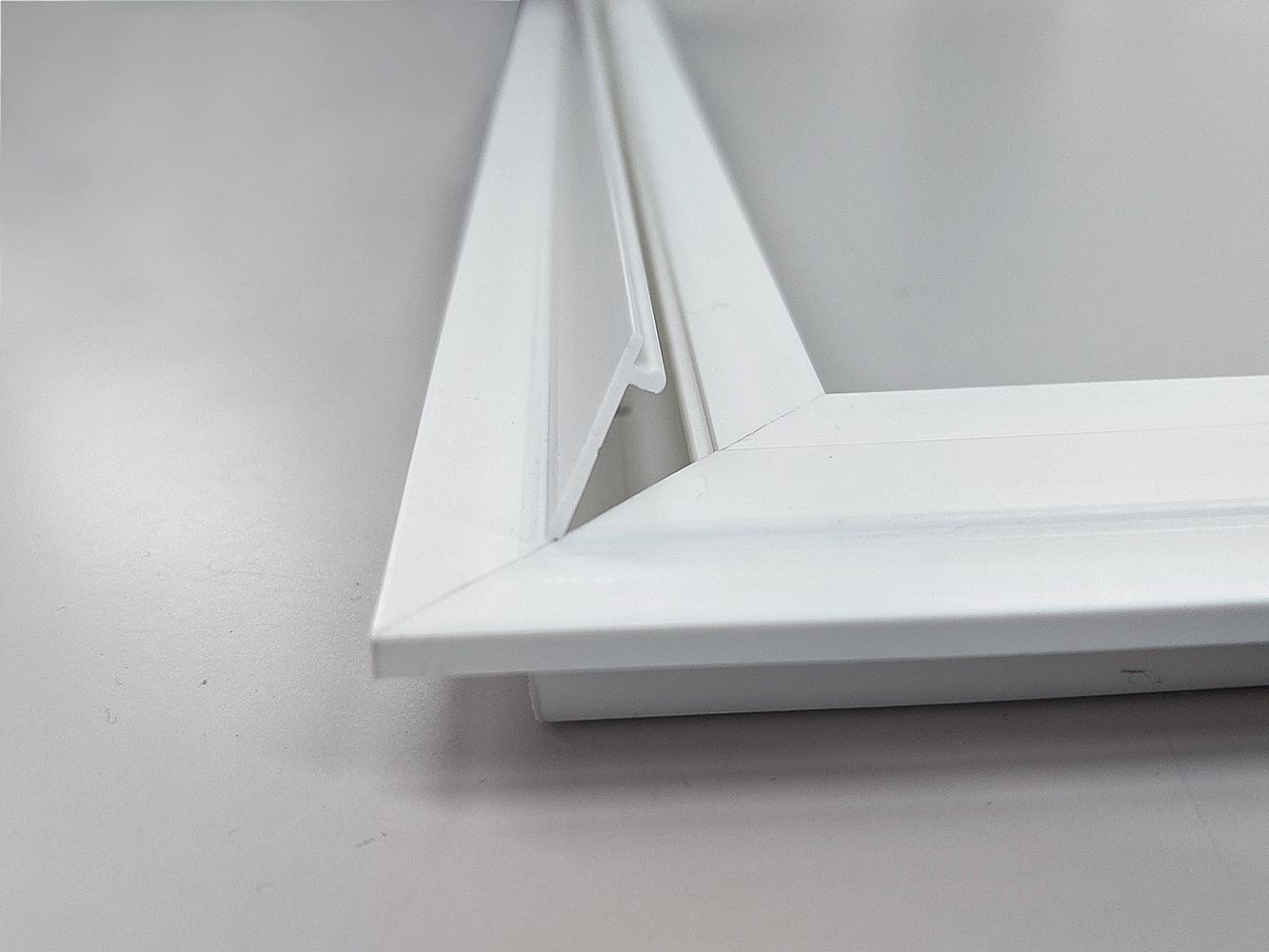

SECONDARY PROCESSING

Fukuvi Vietnam has the capacity for a wide-range of secondary processing. We work with each customer from the design stage to choose the unique method that is most suitable for their product.

The secondary processing area is kept at a constant temperature of 23°C to prevent any unwanted expansion or contraction of the resin.

SECONDARY PROCESSING

Fukuvi Vietnam has the capacity for a wide-range of secondary processing. We work with each customer from the design stage to choose the unique method that is most suitable for their product.

The secondary processing area is kept at a constant temperature of 23°C to prevent any unwanted expansion or contraction of the resin.