OEM SERVICES

The Fukuvi OEM division was created for the purpose of providing our clients with high quality, precision manufactured OEM products and services. We specialize in designing and manufacturing OEM alternatives and replacements and providing clients custom OEM manufacturing services. Our parent company, in Japan, has been providing OEM services to local corporations for decades and has partnered with many car, home appliance, electronics, door/window manufacturers, etc. We are experts in our field of manufacturing and are confident in our ability to accommodate even the most demanding projects. For OEM product and service information, please reach out to us via the “Contact Us” page, and our professional staff will make sure all of your OEM needs and requirements are met.

WHAT OEM SERVICES DO WE PROVIDE?

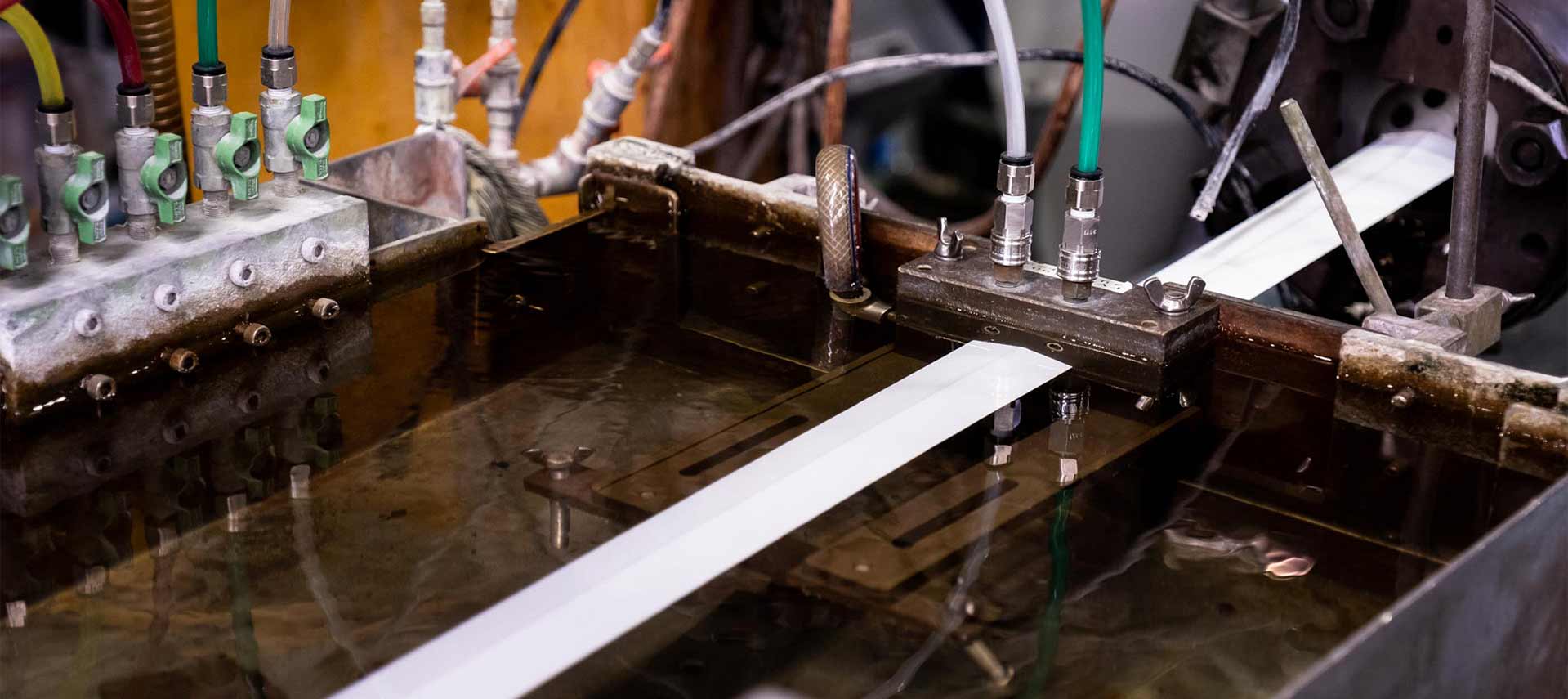

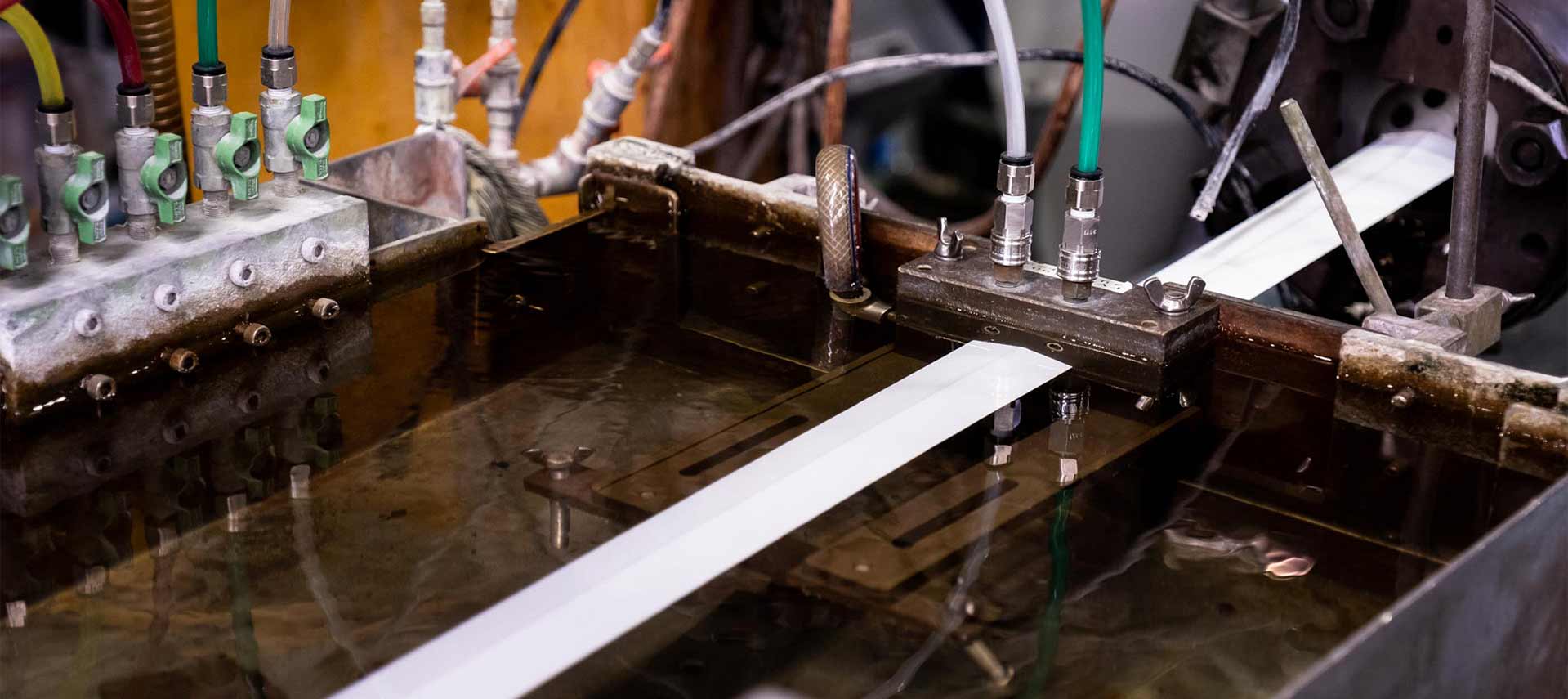

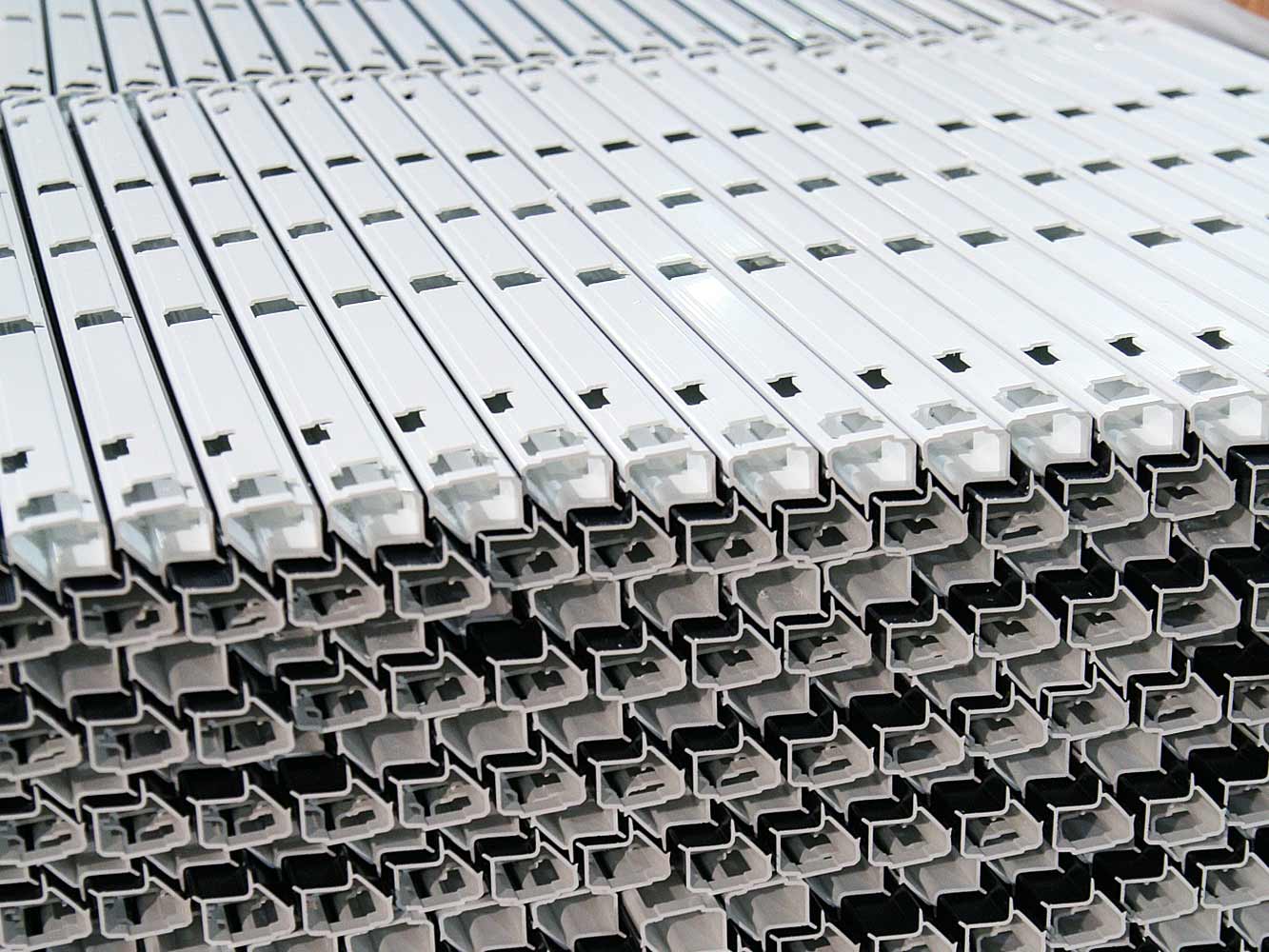

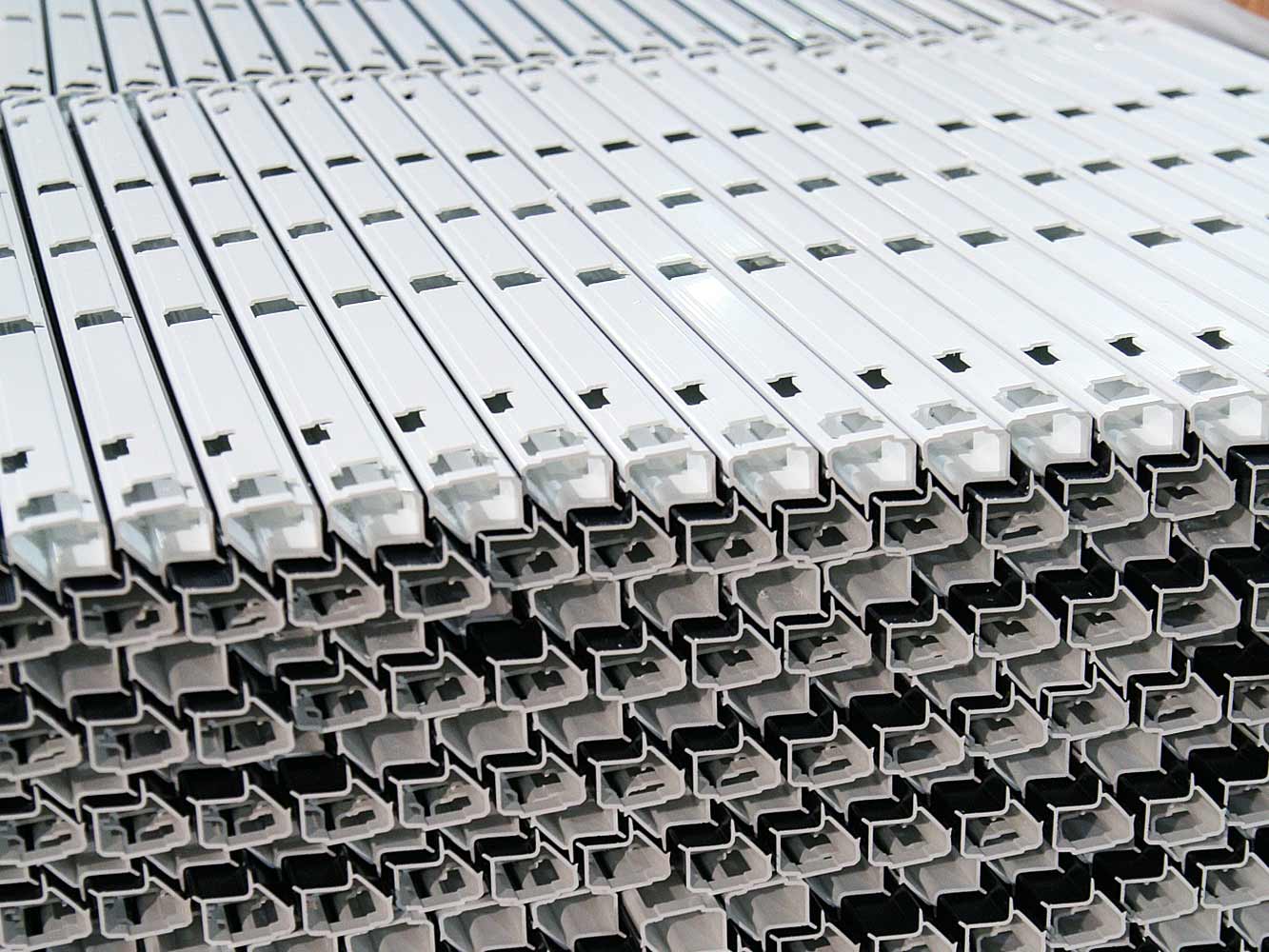

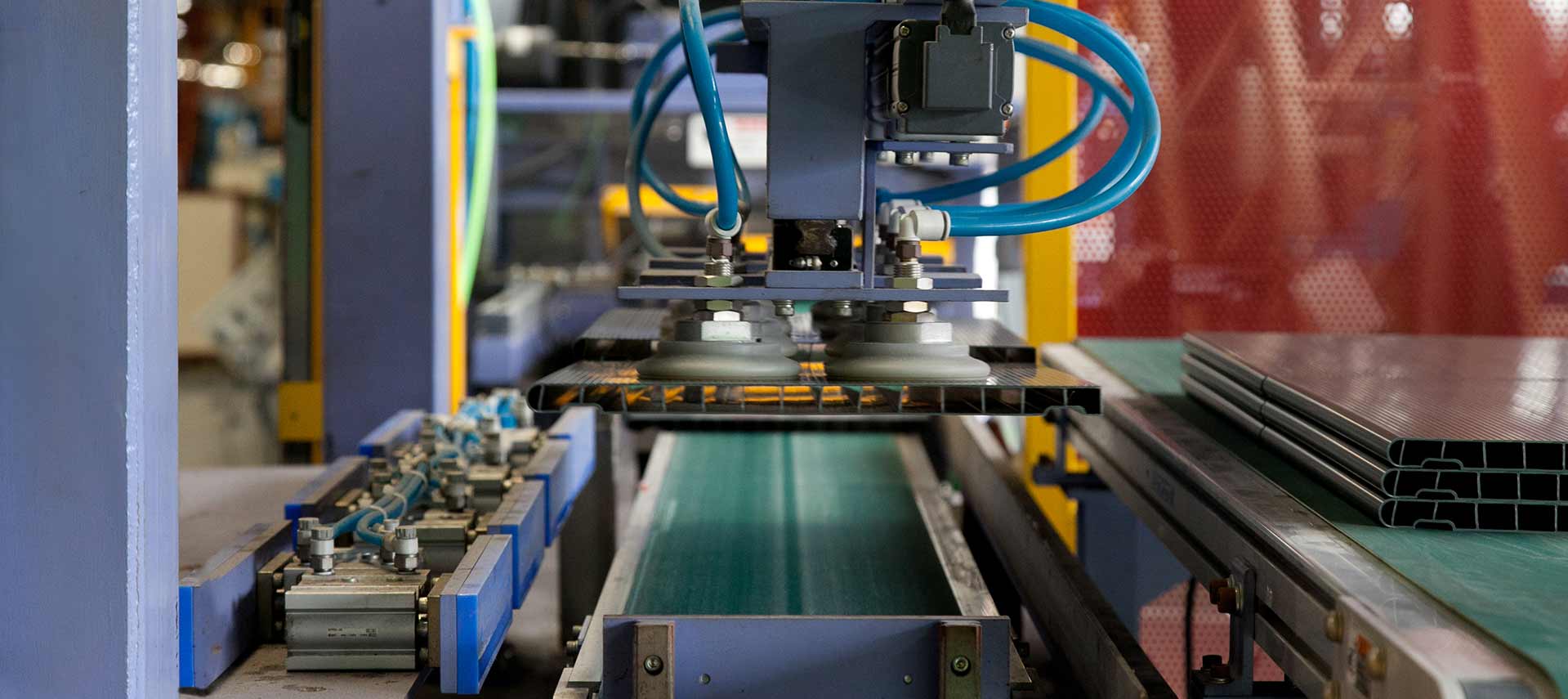

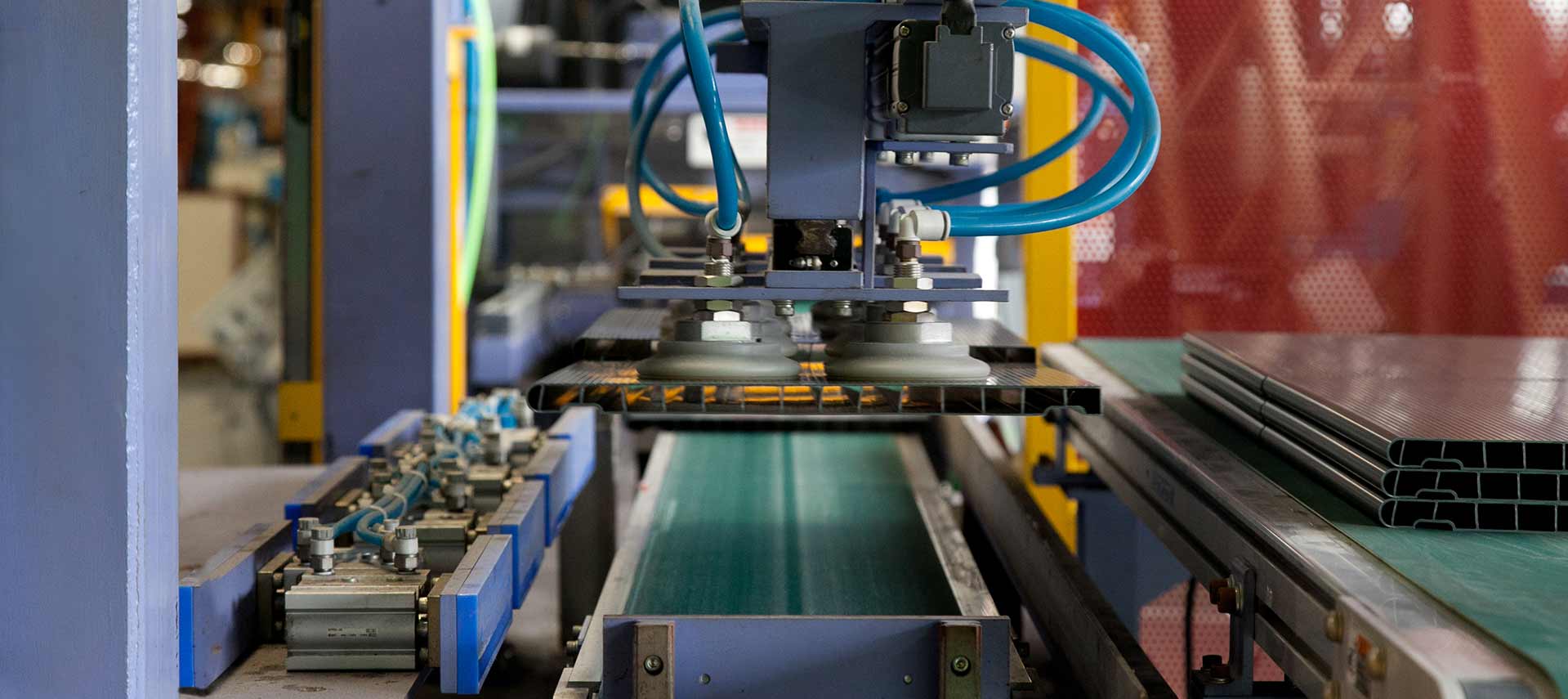

At FUKUVI, we offer our clients complete support in manufacturing products, they design, by using the extrusion molding process. Through the decades of experience within this industry, we have perfected our approach to the extrusion process & have added a variety of capabilities to our manufacturing facilities. Furthermore, we offer additional secondary processing services to our OEM clients like cutting, multi-axis drilling, milling, ultrasonic welding, etc. For a full range of our capabilities please refer to our Technology and Production Capacity pages.

WHAT OEM SERVICES DO WE PROVIDE?

At FUKUVI, we offer our clients complete support in manufacturing products, they design, by using the extrusion molding process. Through the decades of experience within this industry, we have perfected our approach to the extrusion process & have added a variety of capabilities to our manufacturing facilities. Furthermore, we offer additional secondary processing services to our OEM clients like cutting, multi-axis drilling, milling, ultrasonic welding, etc. For a full range of our capabilities please refer to our Technology and Production Capacity pages.

Materials

We specialize in extrusion of a large variety of different plastics and material combinations to produce a product that best meets our customers’ needs and applications.

PVC

S.PVC

Semi-Rigid PVC

ABS

R.ABS

ASA, SAS

HIPS

PMMA

PC

PP

HDPE

Materials

We specialize in extrusion of a large variety of different plastics and material combinations to produce a product that best meets our customers’ needs and applications.

PVC

S.PVC

Semi-Rigid PVC

ABS

R.ABS

ASA, SAS

HIPS

PMMA

PC

PP

HDPE

EXAMPLES OF OEM APPLICATIONS

We work with a variety of large and small companies, from all industries, who require custom OEM parts to be manufactured for their products to be complete and ready for use/sale. Here are some examples of the industries and types of OEM parts that we manufacture for our clients. This is just a short list for reference.

AUTOMOTIVE

- Light Cover/Diffuser

- Molding

- AC Duct

- Refrigerator

- Gasket

- Door Frame

- Protector

CAR:

- Door Molding

- Wire Harness Protector

RESIDENTIAL

COMMERCIAL/HOME REFRIGERATOR:

- Molding

- Door Frame

- Gasket

WASHING MACHINE:

- Molding

TV:

- TV Frame Bezel

- Molding

Air-Conditioning:

- Frame

- Molding

FURNITURE

Conference Table:

- Modesty Panel

Office Partition:

- Various parts & sizes

Cupboard:

- Rail

- Molding

- Protecting Insect Taper

Nursing Bed:

- Bumper

- Edge Cover

OFFICE

Scanner:

- Cover Frame

- Molding

- Various parts & sizes

EXAMPLES OF OEM APPLICATIONS

We work with a variety of large and small companies, from all industries, who require custom OEM parts to be manufactured for their products to be complete and ready for use/sale. Here are some examples of the industries and types of OEM parts that we manufacture for our clients. This is just a short list for reference.

AUTOMOTIVE

- Light Cover/Diffuser

- Molding

- AC Duct

- Refrigerator

- Gasket

- Door Frame

- Protector

CAR:

- Door Molding

- Wire Harness Protector

RESIDENTIAL

COMMERCIAL/HOME REFRIGERATOR:

- Molding

- Door Frame

- Gasket

WASHING MACHINE:

- Molding

TV:

- TV Frame Bezel

- Molding

Air-Conditioning:

- Frame

- Molding

FURNITURE

Conference Table:

- Modesty Panel

Office Partition:

- Various parts & sizes

Cupboard:

- Rail

- Molding

- Protecting Insect Taper

Nursing Bed:

- Bumper

- Edge Cover

OFFICE

Scanner:

- Cover Frame

- Molding

- Various parts & sizes

AUTOMOTIVE

BUS:

- Light Cover/Diffuser

- Molding

- AC Duct

- Refrigerator

TRUCK:

- Gasket

- Door Frame

- Protector

CAR:

- Door Molding

- Wire Harness Protector

HOME

COMMERCIAL/HOME REFRIGERATOR:

- Molding

- Door Frame

- Gasket

WASHING MACHINE:

- Molding

TV:

- TV Frame Bezel

- Molding

Air-Conditioning:

- Frame

- Molding

FURNITURE

Conference Table:

- Modesty Panel

Office Partition:

- Various parts & sizes

Cupboard:

- Rail

- Molding

- Protecting Insect Taper

Nursing Bed:

- Bumper

- Edge Cover

OFFICE

Office Equipment

- Various parts & sizes

Scanner:

- Cover Frame

- Molding

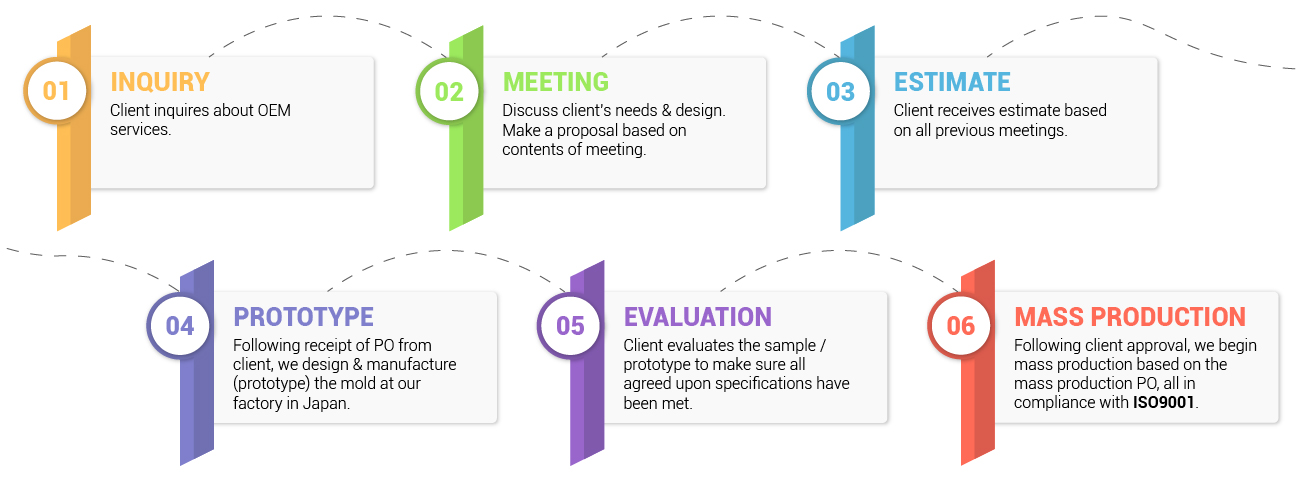

OEM SERVICE FLOWCHART

OEM SERVICE FLOWCHART

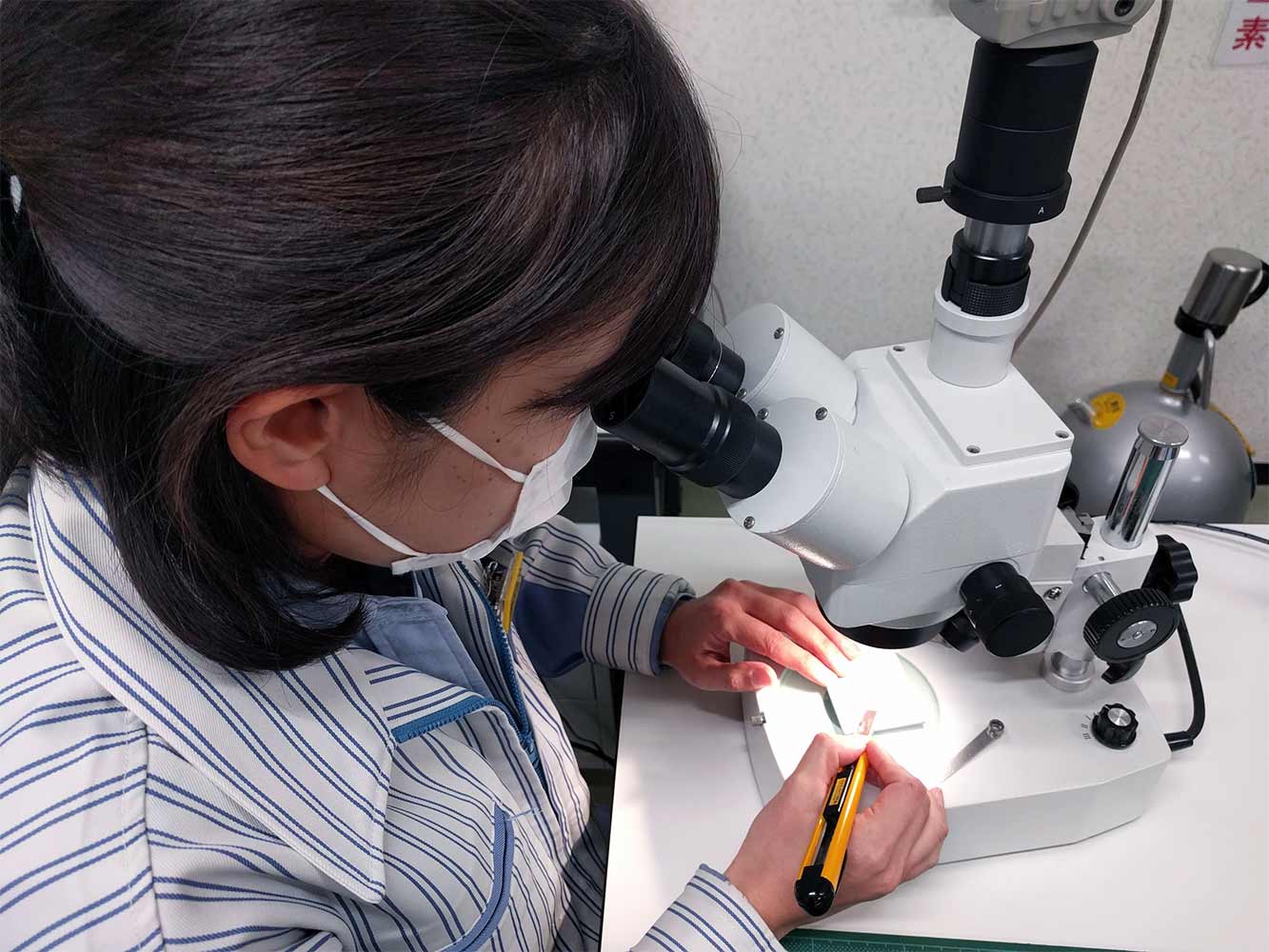

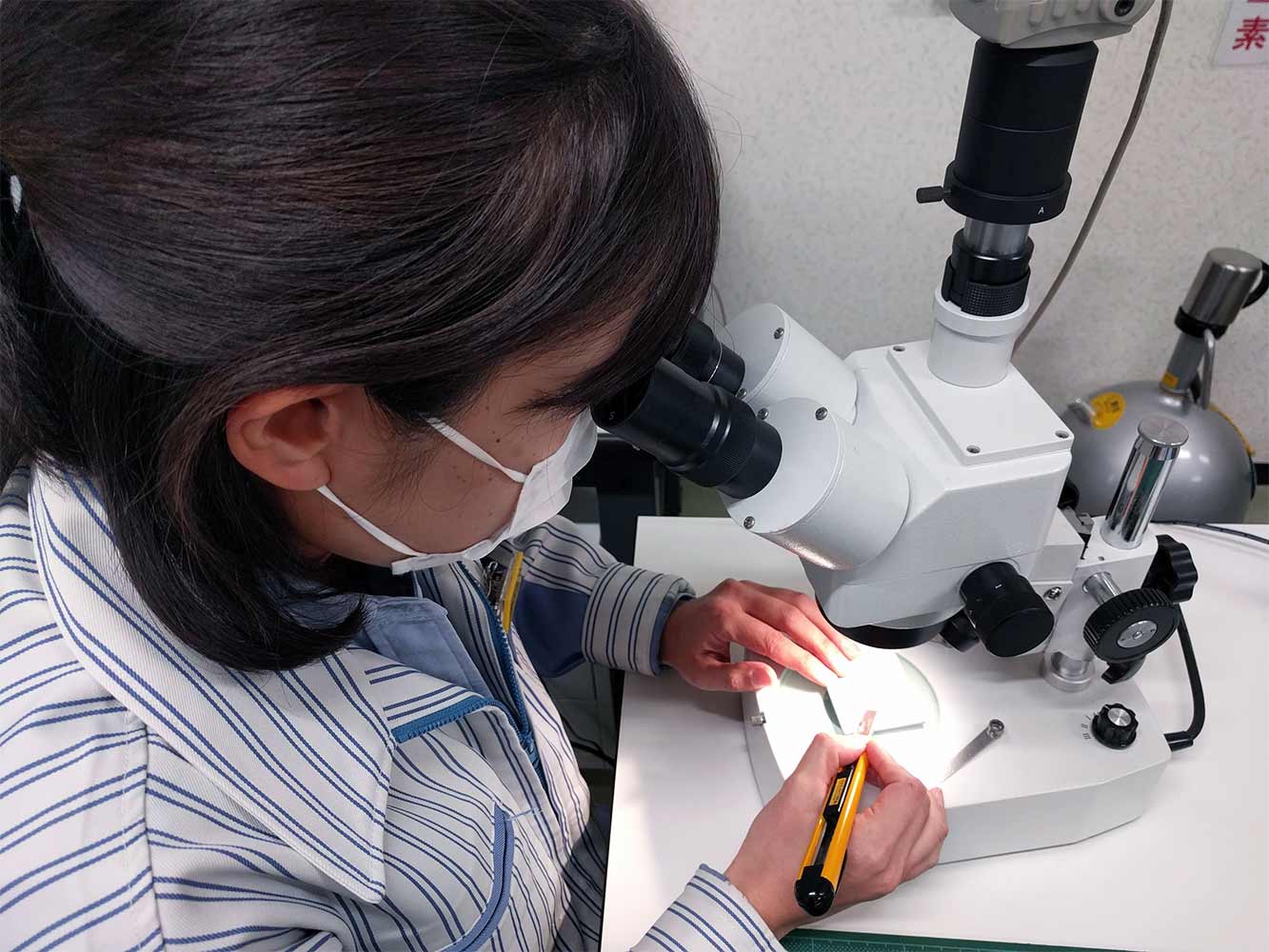

PRECISION MANUFACTURING

With decades of experience in providing OEM manufacturing services to various industry leading companies, and through extensive training of our employees, we are able to provide OEM manufacturing services with extreme precision. We guarantee high quality manufacturing within client specifications.

PRECISION MANUFACTURING

With decades of experience in providing OEM manufacturing services to various industry leading companies, and through extensive training of our employees, we are able to provide OEM manufacturing services with extreme precision. We guarantee high quality manufacturing within client specifications.

High Quality Materials

All OEM products are manufactured from the highest quality materials to ensure precision, longevity & high quality product that our clients can depend on. Regardless of the material used during the manufacturing process our clients can expect that those materials will be of the best quality available.

HIGH QUALITY MATERIALS

All OEM products are manufactured from the highest quality materials to ensure precision, longevity & high quality product that our clients can depend on. Regardless of the material used during the manufacturing process our clients can expect that those materials will be of the best quality available.

OUR TECHNOLOGY

Throughout the years, we at Fukuvi, have continued to add & perfect new extrusion methods to our catalogue of capabilities. At Fukuvi Vietnam, we have the most requested extrusion methods available for OEM use, while at the same time we manufacture our own branded products using the same technologies. We are constantly manufacturing products using all of the different extrusion methods, which means that our employees are continuously gaining experience & never are out of practice.

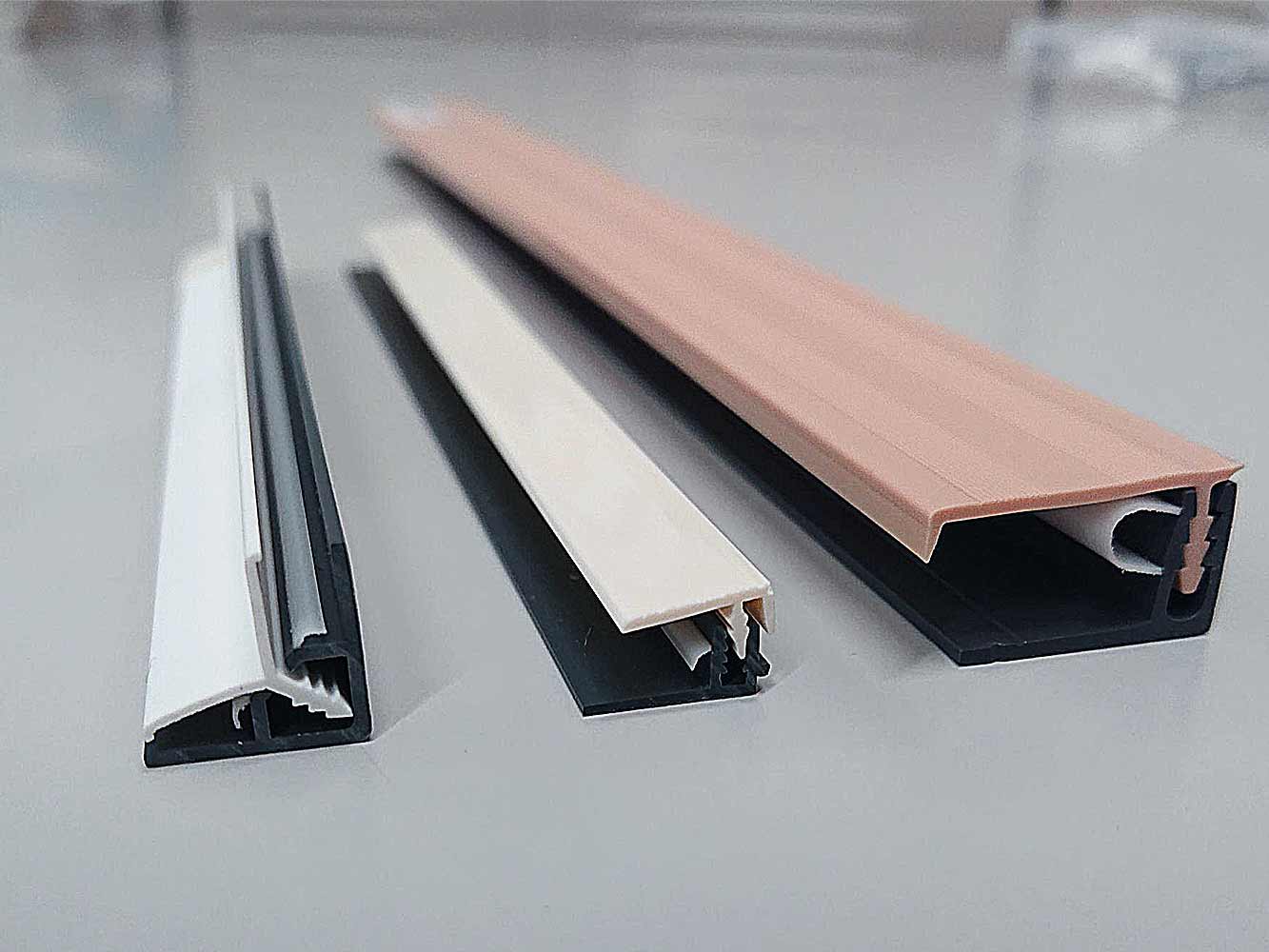

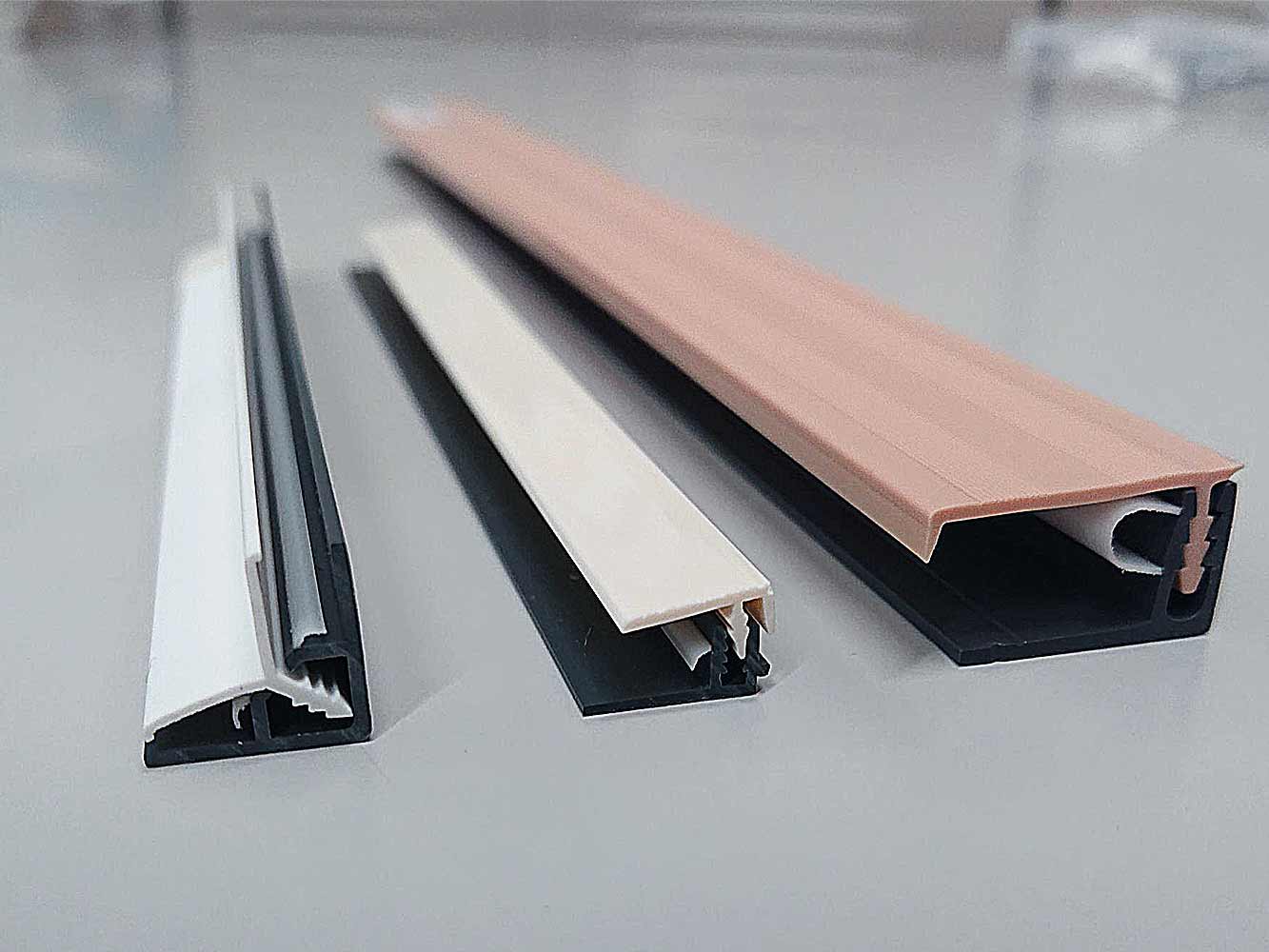

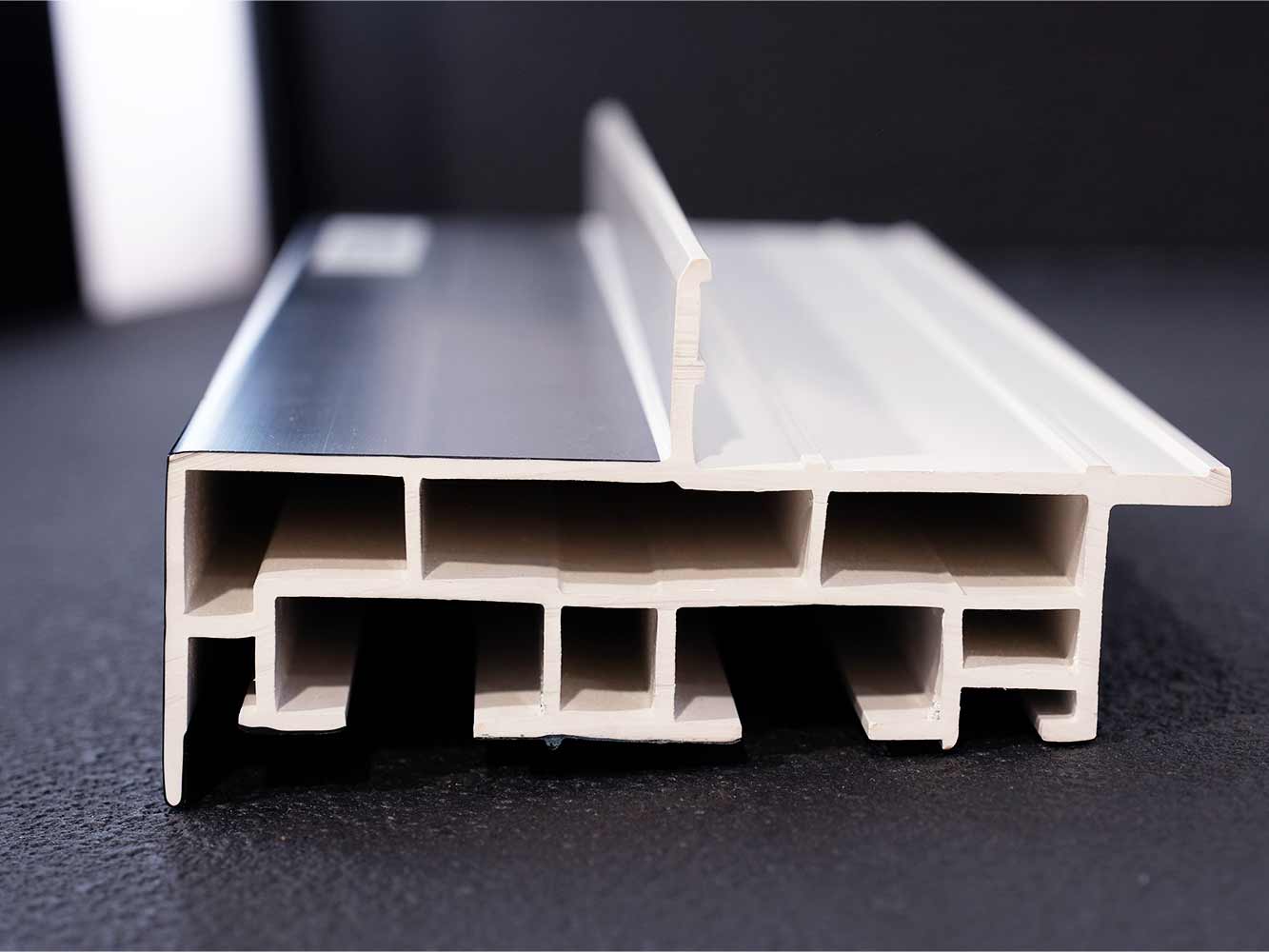

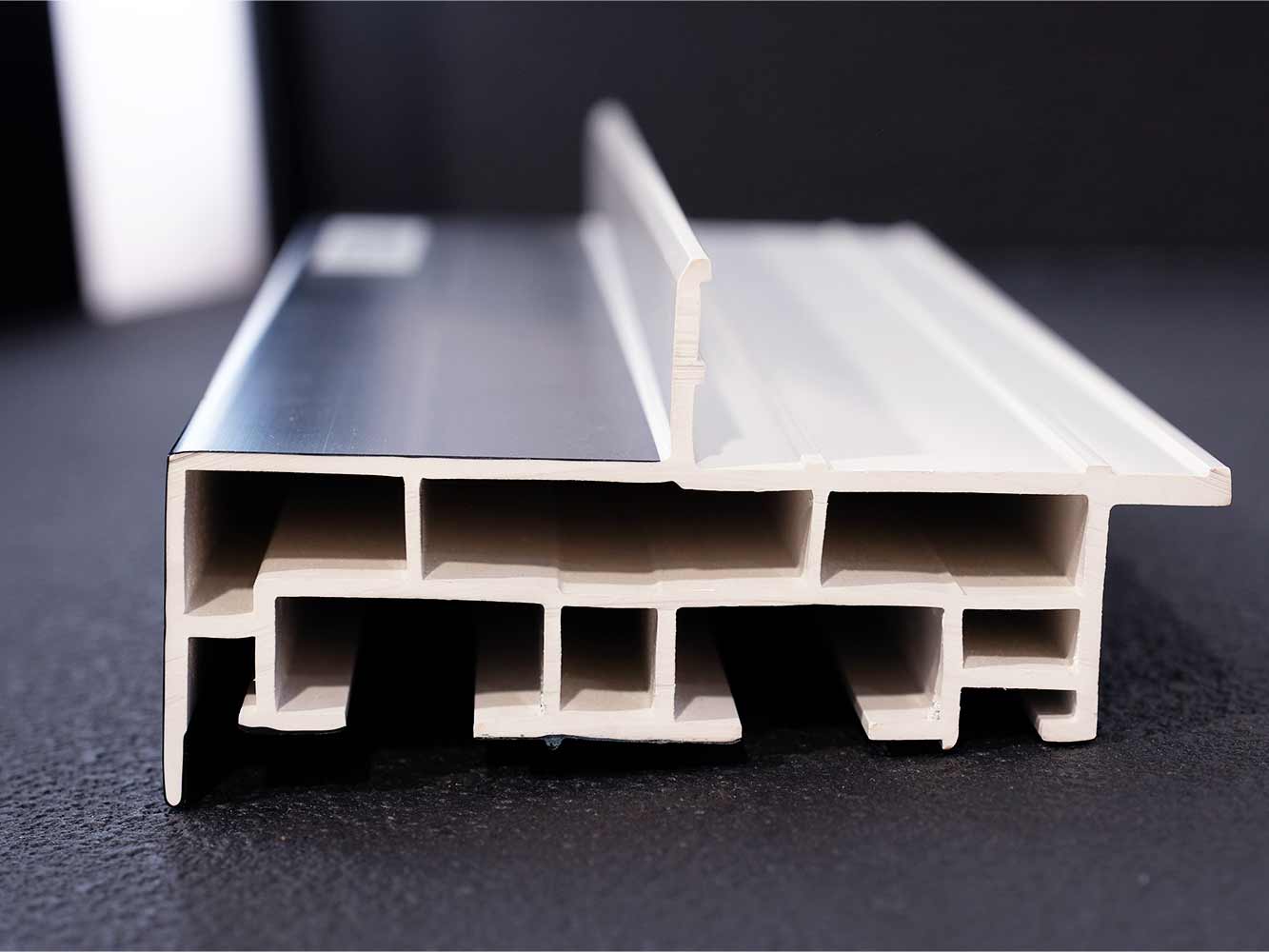

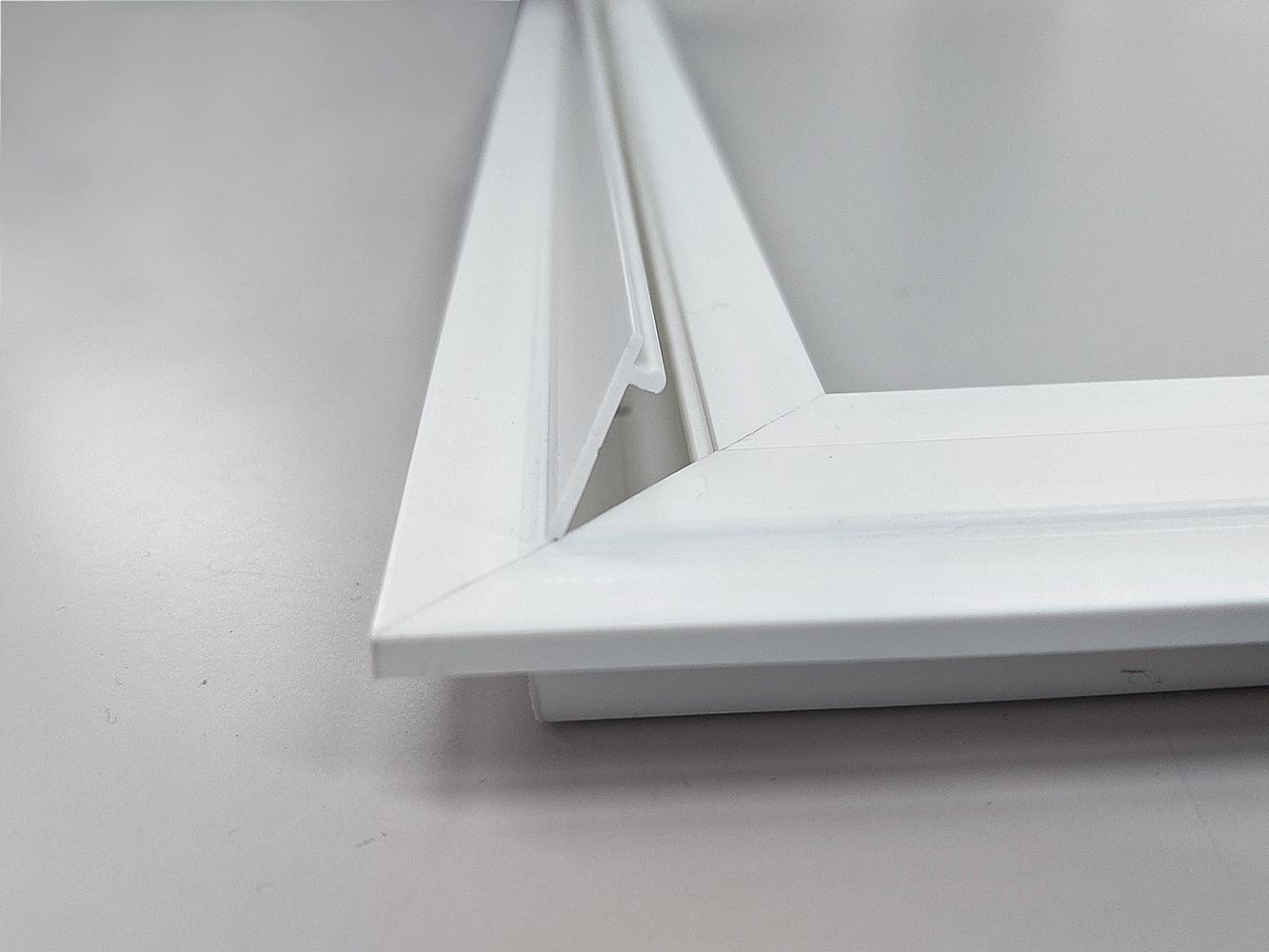

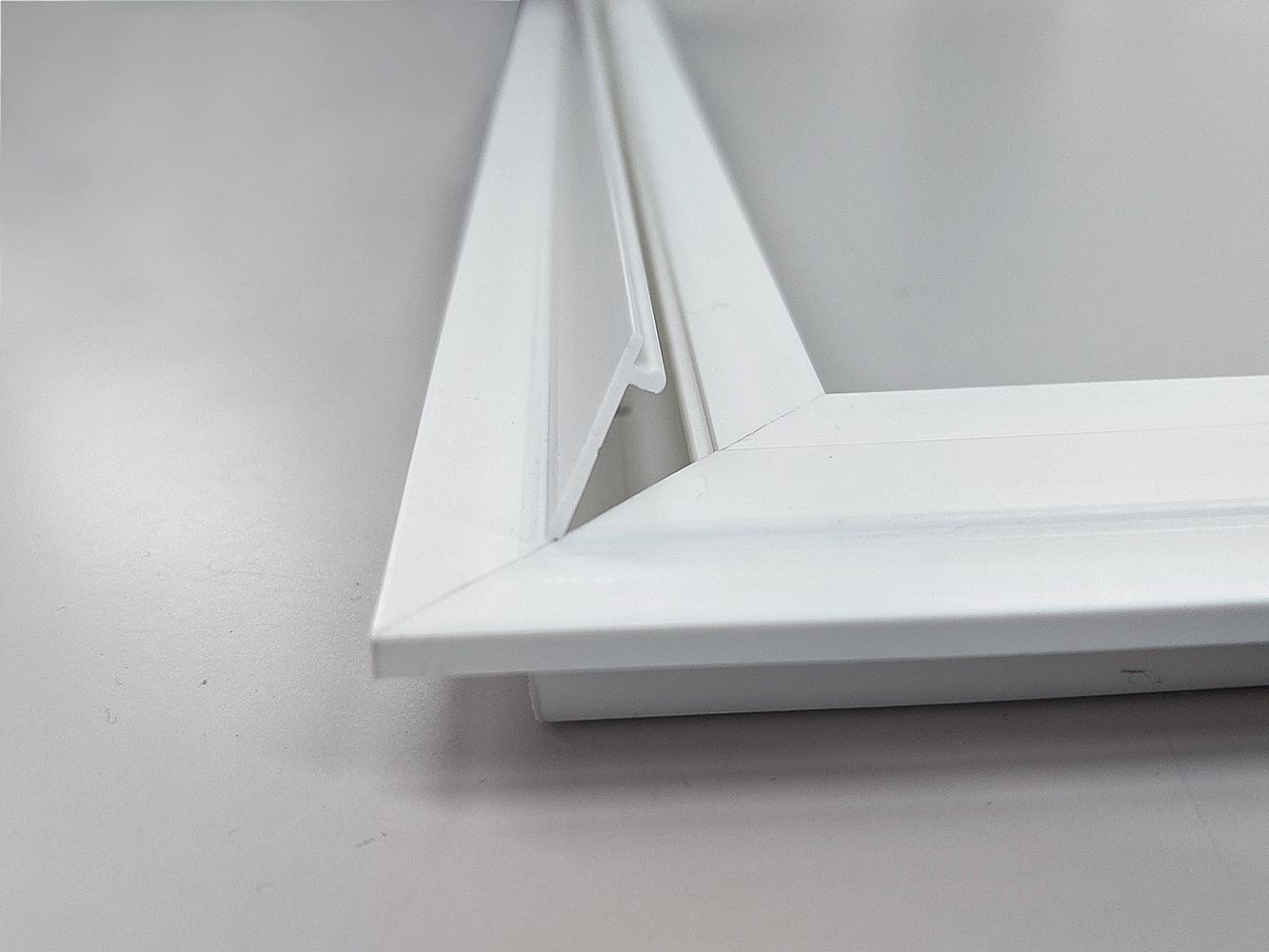

CO-EXTRUSION

Co-extrusion is Fukuvi’s core capability. We can extrude rigid and flexible materials together for a dual durometer extrusion with added value and function. We can also co-extrude different types of materials for improved cosmetic surfaces or weather resistant performance. Extrusion molding is capable of producing very complex cross-sections and using multiple materials in a single mold.

CO-EXTRUSION

Co-extrusion is Fukuvi’s core capability. We can extrude rigid and flexible materials together for a dual durometer extrusion with added value and function. We can also co-extrude different types of materials for improved cosmetic surfaces or weather resistant performance. Extrusion molding is capable of producing very complex cross-sections and using multiple materials in a single mold.

MATERIAL COMBINATIONS

Fukuvi can expertly co-extrude a product which combines two different materials. Combining multiple materials allows you to create enhanced functions and add high value to the parts we extrude.

Benefits of combining materials:

- Combine a light-weight interior with a hard, durable surface

- Combine different colors for enhanced style

- Combine hard and soft materials in order to create a stable product with a hinge or cushion

MATERIAL COMBINATIONS

Fukuvi can expertly co-extrude a product which combines two different materials. Combining multiple materials allows you to create enhanced functions and add high value to the parts we extrude.

Benefits of combining materials:

- Combine a light-weight interior with a hard, durable surface

- Combine different colors for enhanced style

- Combine hard and soft materials in order to create a stable product with a hinge or cushion

DECORATIVE PRODUCTS

Using co-extrusion we can create products with added design elements.

Examples include:

- Metallic

- Brushed Aluminum

- Wood Grain

- Bamboo

- Embossing

- ETC....

DECORATIVE PRODUCTS

Using co-extrusion we can create products with added design elements.

Examples include:

- Metallic

- Brushed Aluminum

- Wood Grain

- Bamboo

- Embossing

- ETC....

FUNCTIONALITY

Fukvui can add various functions to products using our superior co-extruding techniques.

Examples include:

- Increased weather resistance (add PMMA to the surface of base materials)

- Phosphorescence/Luminescence

- Antibacterial/Antiviral surface

- Hinges

- Etc...

FUNCTIONALITY

Fukvui can add various functions to products using our superior co-extruding techniques.

Examples include:

- Increased weather resistance (add PMMA to the surface of base materials)

- Phosphorescence/Luminescence

- Antibacterial/Antiviral surface

- Hinges

- Etc...

LAMINATION / FILM / ADHESIVES

By attaching an aluminum film we can create products which have metallic designs while keeping the high functionality of plastic. These are great substitutes for metal products. We can also add double-sided tape or masking tape to products.

LAMINATION / FILM / ADHESIVES

By attaching an aluminum film we can create products which have metallic designs while keeping the high functionality of plastic. These are great substitutes for metal products. We can also add double-sided tape or masking tape to products.

STRETCHING (SWAGGING)

By stretching the plastic while extruding it (also known as swaging) we can add strength to our extruded products. Depending on the resin mixture and stretching method used spring and wire characteristics can be added.

STRETCHING (SWAGING)

By stretching the plastic while extruding it (also known as swaging) we can add strength to our extruded products. Depending on the resin mixture and stretching method used spring and wire characteristics can be added.

SECONDARY PROCESSING

Fukuvi Vietnam has the capacity for a wide-range of secondary processing. We work with each customer from the design stage to choose the unique method that is most suitable for their product.

The secondary processing area is kept at a constant temperature of 23°C to prevent any unwanted expansion or contraction of the resin.

SECONDARY PROCESSING

Fukuvi Vietnam has the capacity for a wide-range of secondary processing. We work with each customer from the design stage to choose the unique method that is most suitable for their product.

The secondary processing area is kept at a constant temperature of 23°C to prevent any unwanted expansion or contraction of the resin.

PRODUCTION CAPACITY

Our FUKUVI Vietnam manufacturing facility has grown significantly since its opening and we are constantly adding capacity and capabilities to better serve our clients. 13 Extrusion lines with a capacity of 100 tons per month, along with a variety of secondary processing services, help us make sure our clients receive the best product exactly when they expect it. We completely support 24-hour operation of all extrusion lines and secondary processing.

EXTRUSION

- 13 Extrusion Lines

- 100 Tons/Month

- Twin Screw Extruder: 60mm

- Single Screw Extruder: 40mm, 50mm, 65mm

- Co-Extruder

EXTRUSION

- 13 Extrusion Lines

- 100 Tons/Month

- Twin Screw Extruder: 60mm

- Single Screw Extruder: 40mm, 50mm, 65mm

- Co-Extruder

SECONDARY PROCESSING

- Cutting

- Multi-Axis Drilling

- Press (3T)

- Wide Press (10T)

- NC Router Machine

- Milling Machine

- Ultrasonic Welding

- Annealing Machine

SECONDARY PROCESSING

- Cutting

- Multi-Axis Drilling

- Press (3T)

- Wide Press (10T)

- NC Router Machine

- Milling Machine

- Ultrasonic Welding

- Annealing Machine

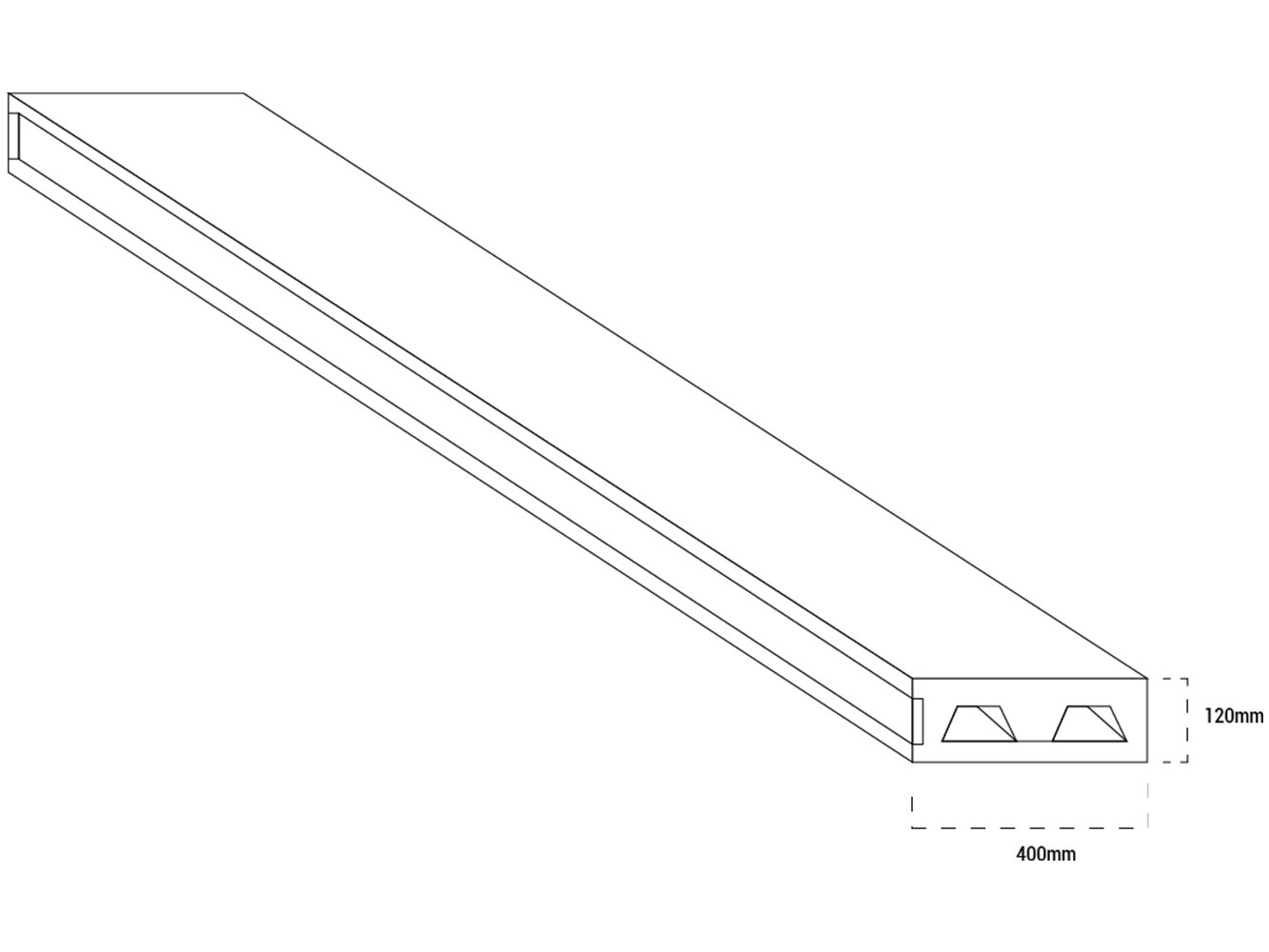

DIMENSIONS

- Up to 400mm in Width

- Up to 120mm in Height

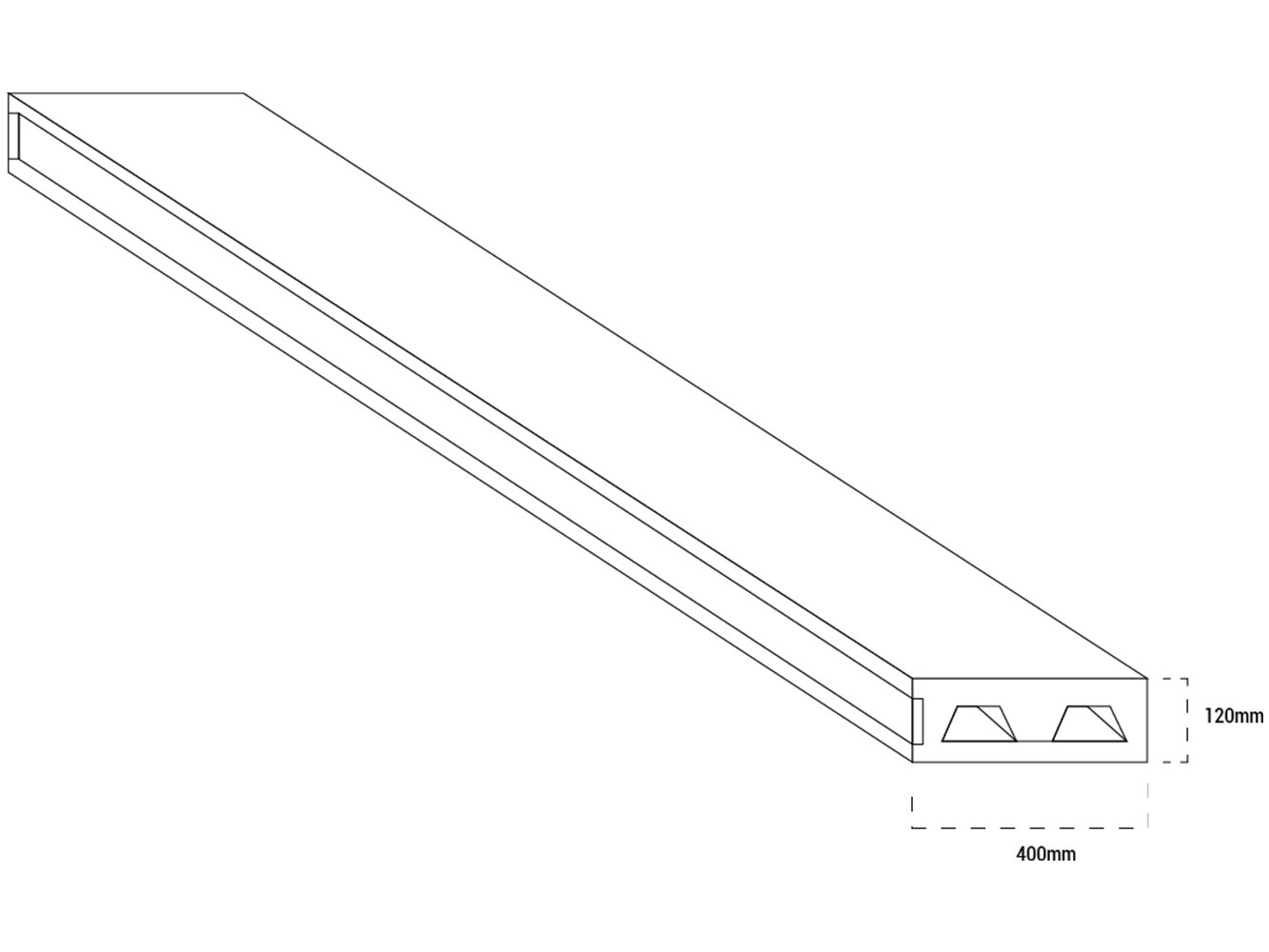

DIMENSIONS

- Up to 400mm in Width

- Up to 120mm in Height

24hr OPERATION

We support 24-hour operation on all extrusion lines and secondary processing.

24hr OPERATION

We support 24-hour operation on all extrusion lines and secondary processing.